The industrial vertical is changing, and more so now than in recent history, The World Economic Forum has long heralded that “Manufacturing has experienced a decade of productivity stagnation and demand fragmentation; innovation is long overdue.”

This past year I have been privileged to meet with over 40 customers, all of whom are trying to solve industry challenges with the help of AI. While these conversations have spanned a range of industries – Cement, Mining, Steel, Glass, Pharmaceutical, Utilities, and more, they have several things in common:

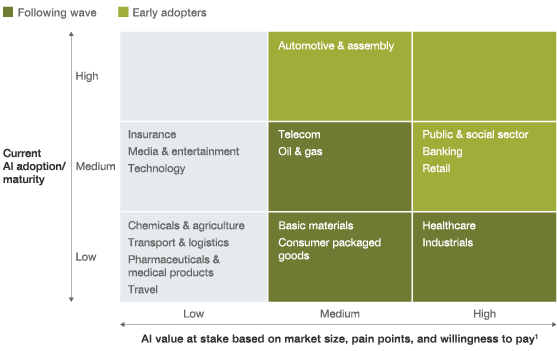

1. While the AI adoption spectrum is broad, it is not too late for fast followers… yet: Granted that some verticals are new to the bandwagon for various reasons, the level of enthusiasm around AI is consistent and electrifying. Early AI adopters1 (e.g., Retail and Banking) have reaped the benefits (Chart 1), and it has caught the eye of industrial innovators and naysayers alike.

[Chart 1] McKinsey & Company: Artificial intelligence: The time to act is now

On one end of the spectrum, some industry leaders are zooming past the basics: digitization, cloud infrastructure, monitoring and dashboards. They are putting this newly acquired data to good use through AI-driven advanced analytics (e.g., uncovering patterns through system of systems) and automating complex processes. Some early adopters are implementing as many as 100 digital transformation initiatives simultaneously or using AI to automate their core production processes across 30+ plants.

On the other end of the spectrum, some folks are now realizing that AI is not “a futuristic idea in some R&D shop.” They still need to understand how AI can provide real value and balance the ROI with their limited resources. As innovators continue to pull ahead because of their newly realized benefits, AI will become a competitive advantage that will force naysayers to adopt or become displaced by their digitally mature competitors.

Despite the wide gap between Industrial early adopters and followers, the breakneck speed of advancement in the Industrial AI/ML space over the last three years affords a unique advantage for these newcomers. They can skip many of the expensive intermediate steps (e.g., significant investments in data aggregation infrastructure, dashboards and monitoring centers) and gain the same AI benefits as the savvier early adopters. In short, for those that don’t want to become laggards that fall by the wayside, the time to start adopting AI is now, before the chasm of AI-driven competitive advantage gets insurmountable.

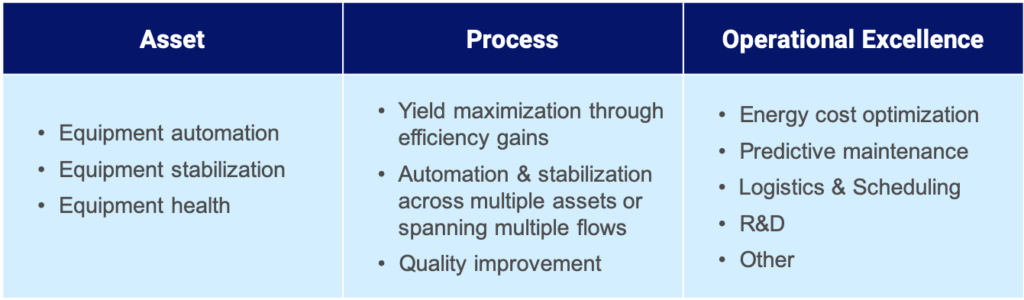

2. While there is a range of AI adoption, some common themes persist regardless of the vertical focus. These themes are not new; they have always been a focus area for manufacturing – improving sustainability, maximizing yield, reducing operating costs, reducing downtime, etc. In the constant quest for improvement across multiple operating metrics, it is becoming evident that AI can be a source of sustainable advantage. Across the board, manufacturers are looking to use AI to solve complex problems they have not been able to tackle through legacy software. Most initiatives fall into the following categories:

Through the application of AI technology, incremental benefits apply across the entire manufacturing value chain. Manufacturers are trying to maximize production and sales at the lowest possible operating cost while improving the quality of their products. Their suppliers and buyers are trying to do the same thing, such as optimizing their supply chain logistics, fleet management, and asset & process optimization.

Typical AI-driven improvements provide a savings or value added improvements ranging from 2% to 7% to many multiples after that. In my experience, these extremely high gains require:

- Strong sponsorship from the C-suite

- Effective change management

- Leveraging an ecosystem…. Not trying to do everything in-house

- Significant collaboration between SMEs and AI/Data Science teams

While Industrial verticals deal with complex problems and therefore adopt new technologies at a more conservative pace, the good news is that the technology itself is proving its value in a number of places. And these factors make the Industrial AI an exciting space.